-

Product DescriptionCompany Info.<>

- Model:

- QC-608W

- Processing customization:

- No

- Overall dimension:

- 450*450*1200 mm

- Weight:

- 150 kg

- Applicable scope:

- 0-2000N

- Packing quantity:

- 1

- working power supply:

- 220

- power:

- 800W

- pressure plate:

- is equipped with a

- speed:

- 3-75 beats/min

- motor:

- servo motor

Sponge latex repeated compression fatigue tester is a kind of testing equipment, which is used to simulate the stress deformation behavior of sponge materials under repeated compression loading. It consists of shell structure, power system, control system, sample fixture and safety protection system. By precisely controlling the compressive loading parameters, the machine can evaluate the fatigue life, elastic recovery performance and structural changes of sponge materials.

The main functions of the sponge repeated compression fatigue tester include:

-

Simulate the compression deformation and recovery process in actual application scenarios, obtain the durability of sponge materials through long-term cyclic loading, and predict their service life, thus providing scientific basis for product design and improvement.

-

Provide precise load control and monitoring to ensure reliability and accuracy of test results.

-

Through the analysis and evaluation of test data, manufacturers can understand the fatigue life and durability of materials, thereby improving product design and material selection.

In addition, the sponge cyclic compression fatigue tester has many advantages. For example, it can automatically adjust the height of the sample tray to keep the impact load within the set impact load range; it has an alarm prompt function, and when the test is completed, an alarm prompt will be issued; at the same time, it can also set parameters such as impact load and test times and impact thickness.

In short, the sponge repeated compression fatigue testing machine is a fully functional, highly automated testing equipment, suitable for sponge material performance evaluation and product development.

This machine complies with GB/T 18941 ISO 3385, Flexible Foam Polymeric Materials. Fatigue Determination by Constant Load Impact Method,( QB/T QBT 2819-2006) Determination of Long-term Fatigue Properties of Soft Foam Materials, QCT56-93 Performance Test Methods for Automobile Seat Cushion Materials, Japanese Automobile Industry Standard JASOB408-84.

Sponge Latex Repeated Compression Fatigue Tester Equipment Features:

-

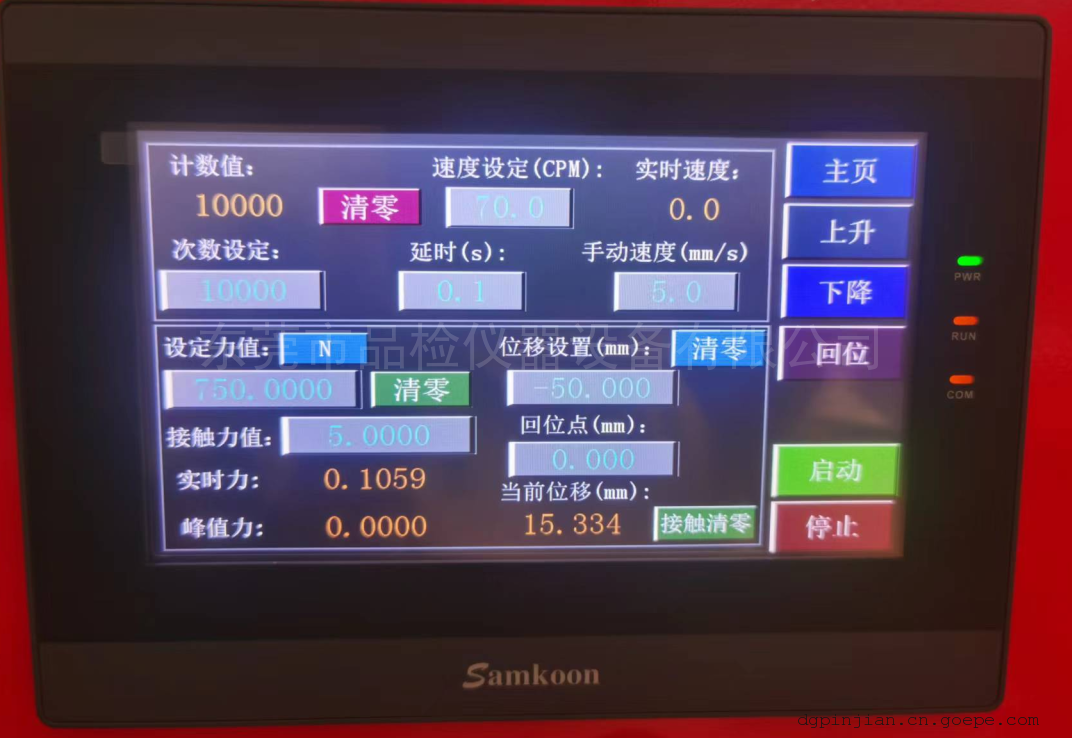

High degree of automation: the test machine through PLC and 7-inch color touch screen parameter setting and operation, can automatically compensate for attenuation force, without manual supervision test.

-

Test speed can be set: * up to 100 times/min, factory standard value 70 times/min.

-

Test times can be set: the machine has a power-off memory function, manual reset, can effectively save real-time test data.

-

Pressure units are optional: kg/N/b.

-

Optional data printing function.

-

Optional configuration for repeated compression and indentation dual function.

Sponge latex repeated compression fatigue testing machine technical parameters:

0. Operation mode: 7 inch touch screen

1. Large loading capacity: 0-2000N.

2, reciprocating compression frequency: 10-100 times/min,(standard requirements: 70 5 times/min)

3. Maximum compression times: 0-999999 can be set

4, reciprocating compression stroke: zui 60mm. (Customizable)

5. Pressure plate diameter: 250 mm 1 mm. Lower edge fillet: R25mm 1mm

6, sample support table: square side length: 500mm thickness: 10mm, aperture: 6.35 mm hole spacing: 20mm

7. Sample size: side length-500mm, thickness-50mm 2mm, shape-rectangle

8, force value display: real-time dynamic display peak

9, the number of experiments: dynamic LCD display, automatically stop after reaching the set value

10. Experiment completed: beep

11. Experimental mode: constant load test, displacement real-time display

12. Sample positioning: It can be positioned according to different test specifications and size to ensure that it will not shift as the test time increases.

13. Host size: length, width and height =800mm*500mm*1200mm

14. Equipment weight: 150KG

15. Motor power: 880W

16. Power supply voltage: 220V/50HZ

Sponge Latex Repeated Compression Fatigue Tester Usage:-

Sample preparation: Select foam or latex samples to be tested and ensure that the sample surface is flat, free of bubbles and impurities.

-

Mounting the sample: Place the sample on the test platform of the tester, ensuring that the sample is in complete contact with the platform surface. If multiple samples need to be tested, multiple samples can be placed simultaneously.

-

Setting parameters: according to the test requirements, set repeated compression times, compression speed and other parameters.

-

Start the equipment: Start the tester and start the test. Observe the deformation of samples during testing and record test data.

-

Data analysis: Data analysis is performed based on recorded test data. Parameters such as compression curve, compression strength, compression set can be generated to evaluate the performance of foam or latex samples. Compare the test results with standard or expected results to determine whether the sample meets the requirements.

-

Clean the equipment: After completing the test, turn off the power and air supply of the testing machine and disconnect the connection. Clean test platform and equipment surfaces to ensure cleanliness and residue free. Maintain equipment and keep it in good condition.

It should be noted that the specific foam latex repeated compression fatigue testing machine use method may vary according to different manufacturers and brands, it is recommended to directly refer to the equipment manual or contact the equipment manufacturer or seller for more detailed and accurate information. At the same time, pay attention to safety during operation, follow operating procedures and avoid accidents.

- Name(chinese)

- Name(English)

- Dongguan city quality inspection instrument and equipment co., ltd

- China credit code

- Identity Verification

- Address

-

Dongguan, Guangdong, China

- Nearby port

- Shenzhen,Guangzhou

Since its establishment in 2013, Dongguan city Quality Inspection Instrument and Equipment Co., Ltd. has manufactured and produced: Wire bending testing machine, copper wire elongation testing machine, alcohol eraser wear testing machine, button life testing machine, microcomputer insertion force testing machine, precision salt water spray testing machine, simulated transportation vibration table, plug wire burst testing machine, terminal wire weight static lifting testing machine, ball falling impact testing machine, fully automatic insertion force testing machine, constant temperature and humidity testing chamber, cold and hot impact testing machine and other equipment, With its excellent quality and excellent services, it has developed rapidly and has become a professional manufacturer capable of independent production, research and development and sales. It has a team of talents with superb production and manufacturing skills and a complete management system, from product material selection, processing process, performance testing, and after-sales service, strictly controls at all levels and division of labor is in place to ensure that satisfactory products are provided to various manufacturers and distributors. Products are manufactured in strict accordance with ISO, ASTM, AATCC, TAPPL, UL, VDE, IEC, ANSI, ASME, CSA, JIS, BS, EN, DIN, SATRA, GB, CNS and other domestic and international standards. Now the company is moving towards the goal of "zero defects" to eliminate the generation and sales of defective products, so that customers from all walks of life can buy with confidence and use them effectively, and strive to become a well-known company in the same industry. The products produced include mobile phones, computers, electronic and electrical appliances, wires and cables, optical fiber cables, plastics, rubber, packaging, paper products, auto parts, metals, hardware, casting and other testing equipment. The products are well received by manufacturers and are exported at home and abroad. The company is located in the important town of Tangxia, Dongguan. The company has complete production equipment, superb technical strength and good quality awareness. In line with the working concepts of reputation, quality, keeping up with the times, and being advanced, the company provides customers with novel and satisfactory products. The company adheres to the operating policy of "people-oriented and customer-oriented" and is willing to cooperate and negotiate business with all new and old customers in the society. Provide customers with satisfactory and high-quality products and services, and put forward valuable opinions.- Name(chinese)

- Name(English)

- Dongguan city quality inspection instrument and equipment co., ltd

- China credit code

- Identity Verification

- Address

-

Dongguan, Guangdong, China

- Nearby port

- Shenzhen,Guangzhou

Since its establishment in 2013, Dongguan city Quality Inspection Instrument and Equipment Co., Ltd. has manufactured and produced: Wire bending testing machine, copper wire elongation testing machine, alcohol eraser wear testing machine, button life testing machine, microcomputer insertion force testing machine, precision salt water spray testing machine, simulated transportation vibration table, plug wire burst testing machine, terminal wire weight static lifting testing machine, ball falling impact testing machine, fully automatic insertion force testing machine, constant temperature and humidity testing chamber, cold and hot impact testing machine and other equipment, With its excellent quality and excellent services, it has developed rapidly and has become a professional manufacturer capable of independent production, research and development and sales. It has a team of talents with superb production and manufacturing skills and a complete management system, from product material selection, processing process, performance testing, and after-sales service, strictly controls at all levels and division of labor is in place to ensure that satisfactory products are provided to various manufacturers and distributors. Products are manufactured in strict accordance with ISO, ASTM, AATCC, TAPPL, UL, VDE, IEC, ANSI, ASME, CSA, JIS, BS, EN, DIN, SATRA, GB, CNS and other domestic and international standards. Now the company is moving towards the goal of "zero defects" to eliminate the generation and sales of defective products, so that customers from all walks of life can buy with confidence and use them effectively, and strive to become a well-known company in the same industry. The products produced include mobile phones, computers, electronic and electrical appliances, wires and cables, optical fiber cables, plastics, rubber, packaging, paper products, auto parts, metals, hardware, casting and other testing equipment. The products are well received by manufacturers and are exported at home and abroad. The company is located in the important town of Tangxia, Dongguan. The company has complete production equipment, superb technical strength and good quality awareness. In line with the working concepts of reputation, quality, keeping up with the times, and being advanced, the company provides customers with novel and satisfactory products. The company adheres to the operating policy of "people-oriented and customer-oriented" and is willing to cooperate and negotiate business with all new and old customers in the society. Provide customers with satisfactory and high-quality products and services, and put forward valuable opinions. -

Send your message to this supplier*From:*To:

Mr. lisanbao

*Message:

Mr. lisanbao

*Message:

Copyright © 2003 - 2026 Goepe.com All rights reserved.